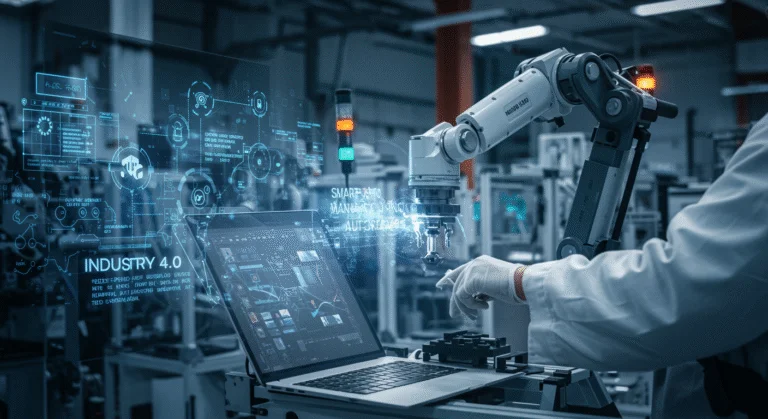

Additive manufacturing (AM) has experienced rapid growth over the past decade. According to a report by Wohler, the global 3D printing industry surpassed $18 billion in 2023 and is expected to continue expanding at a 17% to 20% CAGR. This is the reason for pushing the companies to adopt digital designing tools like SolidWorks.

It helps them to speed up the product development, reduce the prototyping cost, and improve the accuracy in manufacturing.

What is SolidWorks

SolidWorks is a 3D CAD (computer-aided design and CAE (computer-aided engineering) software.

It is developed by Dassault Systèmes. It is used by the engineers and designers for the development of the products from concept to manufacturing.

It is well known for its parametric modelling capabilities. It allows users to create precise 3D models, assemblies, and 2D drawings. It is used across many industries for designing purposes.

Why SolidWorks is a Core Tool for Additive Manufacturing

SolidWorks provides a complete ecosystem for preparing, validating, and optimizing 3D-print-ready models. Nearly 6 million engineers and designers use it globally. Its additive manufacturing (AM) focused features make it one of the top choices for the 3D printing workflows.

Key tools of SolidWorks:

- Print 3D Tools:

It helps to visualize printing orientation, detect thin walls, estimate the build volume, and preview support.

- Topology Optimization:

It automatically reduces the material usage by 30% to 50% while maintaining part strength.

- Lattice and Internal Structure:

It is essential for lightweight aerospace, medical, and automotive components.

- STL/AMF Export with Error Checking:

It ensures watertight, printable files without post-processing issues.

These capabilities are covered extensively in SolidWorks online classes with certificates. It allows the learners to practice with real-world engineering examples.

Core Fundamentals of 3D Printing in SolidWorks

● Designing for Additive Manufacturing (DfAM)

DfAM principles help to avoid costly print failures. SolidWorks makes this easier through draft analysis, overhang detection, and minimum feature size checks. It is so critical. Because over 70% of print failures come from improper geometry preparations.

● Material Simulation and Validation

From plastic-like PLA and ABS to metals such as titanium and Inconel, SolidWorks’ material library allows the simulation of mechanical performance. It helps to ensure the printed part meets real-world requirements.

● Orientation and Support Strategy

Part orientation can influence strength by up to 40%, especially in FDA and SLA printing. SolidWorks helps test multiple orientations to reduce support consumption and improve surface finish.

● Digital-to-Print Workflow

SolidWorks enables easy export to slicers and supports direct integration with professional printers. This helps to reduce manual errors and speeds up prototype cycles by 20% to 30% for many teams.

Why Learning SolidWorks for AM Is a Career Accelerator

Industries like aerospace, healthcare, automotive, and tooling increasingly prefer trained engineers in AM workflows. Completing a SolidWorks online certification course gives designers hands-on experience in preparing production models, something businesses now expect due to the rising adoption of rapid prototyping and low-volume manufacturing.

For the students and the working professionals, enrolling in the SolidWorks online training course provides structured learning, industry-recognized skills, and a strong portfolio of 3D-print-ready designs.

Contact us today to get started!